vega

vega

Surfaces with the highest light reflection

Manufactured with PVD (Physical Vapour Deposition) technology and available in multiple types depending on the specific application required, vega surfaces are characterized by total reflection values of up to 98%, 15% higher than those of anodized aluminum. For the same light intensity, vega achieves significant energy savings and it increases the efficiency of luminaires by up to 20%.

vega95

vega95

PVD vacuum deposition ensures a minimum reflection of 95% to this range of aluminum surfaces, whose finish varies from shiny to diffuse. To meet different light distribution needs, both isotropic and anisotropic surfaces are also available.

Total reflection: 95%

Alloy: 1085 – 1090 – 5005

Thickness: 0,30 mm – 1,00 mm

Width: 1250 mm

Efficiency class: A

vega98

vega98

In projects for which energy saving and efficiency are imperative requirements, vega98 is the most appropriate solution, due to the variety of patterns and finishes (from diffuse to glossy) and the guarantee of at least 98% light reflection, with both isotropic and anisotropic distributions.

Total reflection: 98%

Alloy: 1085 – 1090 – 5005

Thickness: 0,30 mm – 1,00 mm

Width: 1250 mm

Efficiency class: A+

vegauv

vegauv

vega®UV surfaces offer improved performance over anodized materials or other typical reflective surfaces in UV source applications. vega®UV is widely employed in photopolymerization processes, where UV radiation is used to initiate chemical reactions.

In addition, each variant of vega®UV finds its own specific area of use:

- vega®UV-A is used in tanning lamps,as well as in forensic applications and in the evaluation of gems and works of art, where some substances are visible through the phenomenon of fluorescence;

- vega®UV-B is used in the medical field, for instance in psoriasis treatments and other skin diseases;

- vega®UV-C is used in the field of sterilization, for lining the interior walls of medical equipment and devices or for the production of reflective optics. The composition of the layers, optimized for the UV-C band (with wavelengths between 200 nm and 280 nm), increases reflection to more than 91% increasing the effectiveness of UV systems and their sanitizing power.

Alloy: 1085 – 1090

Thickness: 0,30 mm – 1,00 mm

Width: 1250 mm

Reflection Vega UV-A at 360 nm 92% ± 2%

Reflection Vega UV-B at 300 nm 91% ± 2%

Reflection Vega UV-C at 280 nm 91% ± 2%

vega greeN

vega greeN

vega greeN is the new version of optimized surfaces for horticultural applications.. It is available in both the HPS (high-pressure sodium) lamps where it offers up to 4 percent more efficacy than standard materialswith 95% total reflection, and in the version for reflectors and LED sources., thanks to its silver-based PVD coating. In particular, vega greeN LED is suitable for use for crops with different wavelength requirements of light, due to maximum reflection uniformity in the entire range of visible (380-780 nm).

Alloy: 1085 – 1090

Thickness: 0,30 mm – 1,00 mm

Width: 1250 mm

Reflection at 600 nm: 96% ± 2%

Reflection at 650 nm: 95% ± 2%

Reflection at 685 nm: 94% ± 2%

vegaSP

vegaSP

vega SP is a special highly reflective PVD aluminum used for systems that controllably direct natural light into enclosed spaces to improve visual and thermal comfort. These glossy surfaces are characterized first and foremost by a very high total reflection of 98.5% of the visible spectrum, which results in obvious advantages in system efficiency. They also exhibit very low losses due to multiple reflections: an aspect, this one, that is particularly appreciated in light tunnels.. These characteristics are complemented by high uniformity of the visible spectrum and excellent color rendering, resulting in improved visual comfort.

Alloy: 1085 – 1090

Thickness: 0,30 mm – 1,00 mm

Width: 1250 mm

vega energy

vega energy

The vega energy surfaces were developed to maximize optical performance and its durability of secondary reflectors installed on solar concentrating systems: the innovative multilayer hat characterizes these surfaces offers the best combination of optical performance and resistance to temperature so as to ensure a durability efficiency. Both products-available inflat formats as well as in the form of finished reflectors – represent Almeco’s continued commitment to the development of usable surfaces in applications related to the exploitation of renewable energy.

The vega energy range consists of.:

- vega energyHT is designed to maintain constant high reflection levels even at continuous operating temperatures up to 250°C. It is the ideal surface to be used in secondary reflectors of Fresnel systems.. Its special coating greatly reduces the degradation phenomena of the reflective surface, ensuring its high performance for a long time;

- vega energyTS has a special composition that allows it to maintain its reflection performance intact even at operating temperatures above 300°C, while minimizing losses.

Alloy: 1085 – 1090

Thickness: 0,30 mm – 1,00 mm

Width: 1250 mm

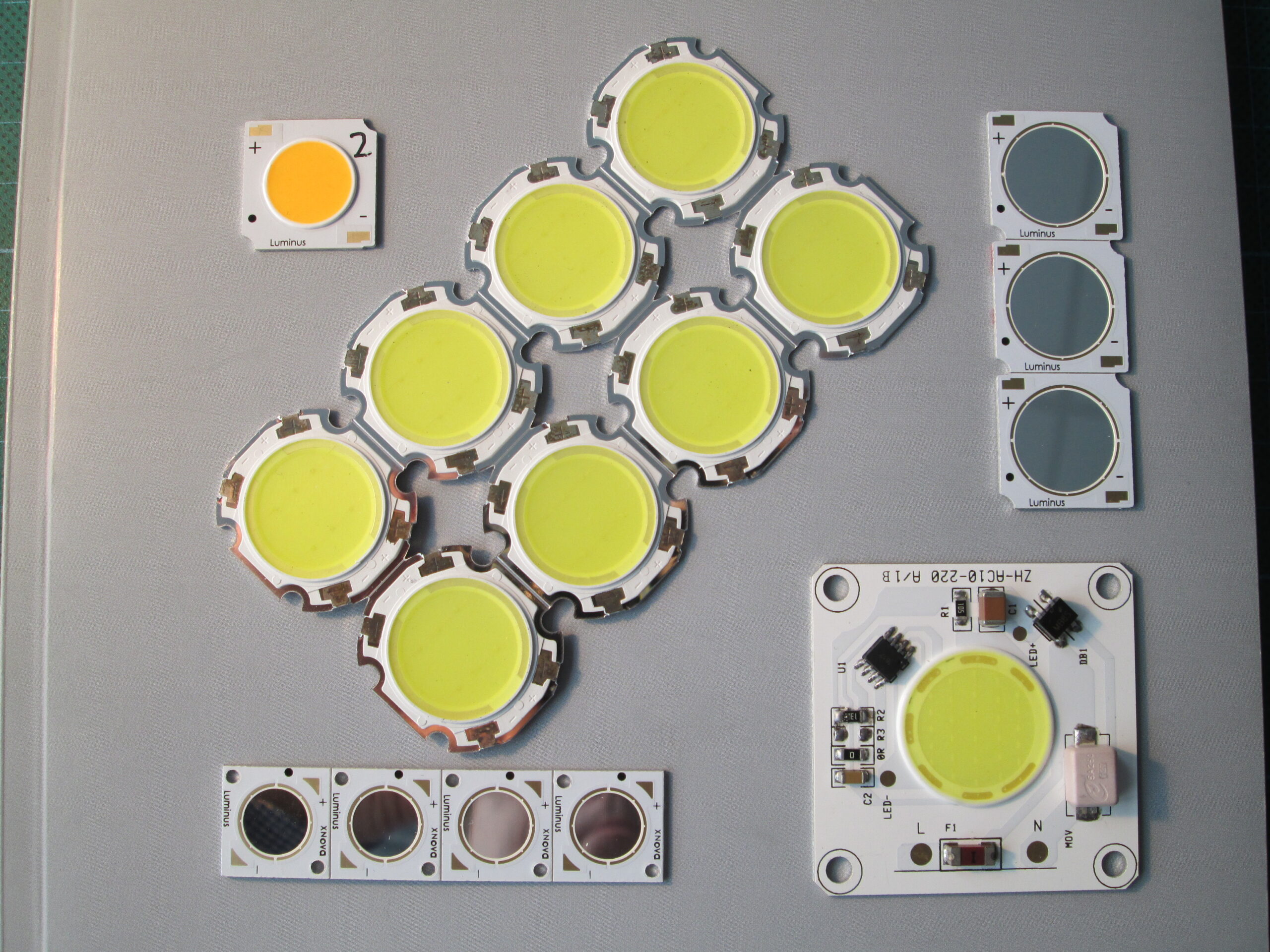

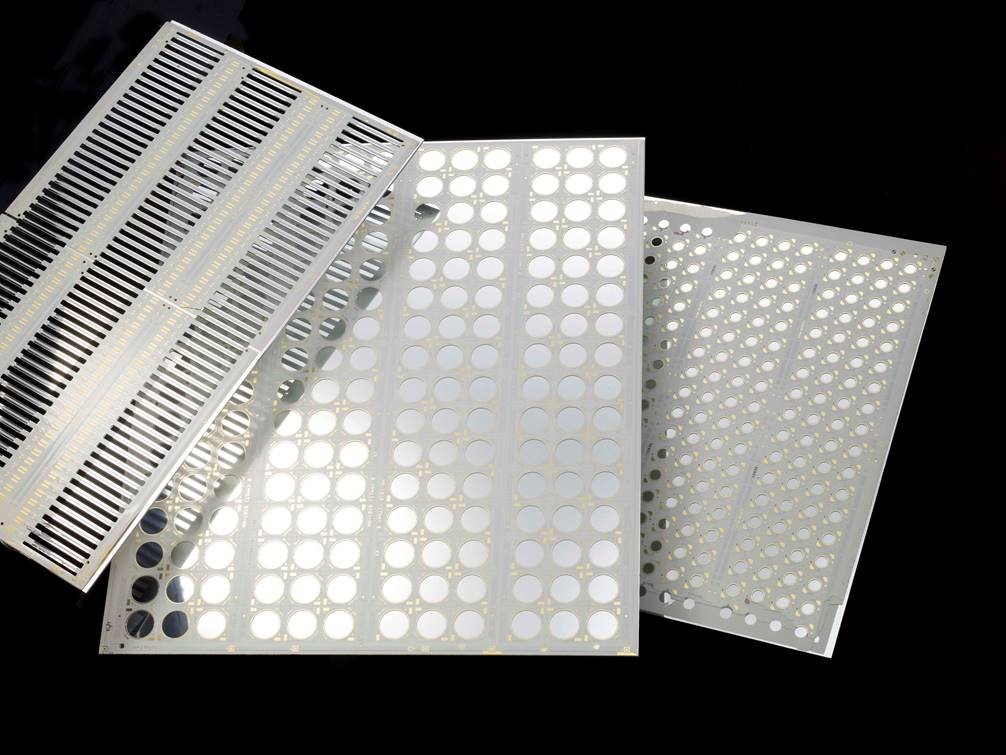

vegaLED on Board

vegaLED on Board

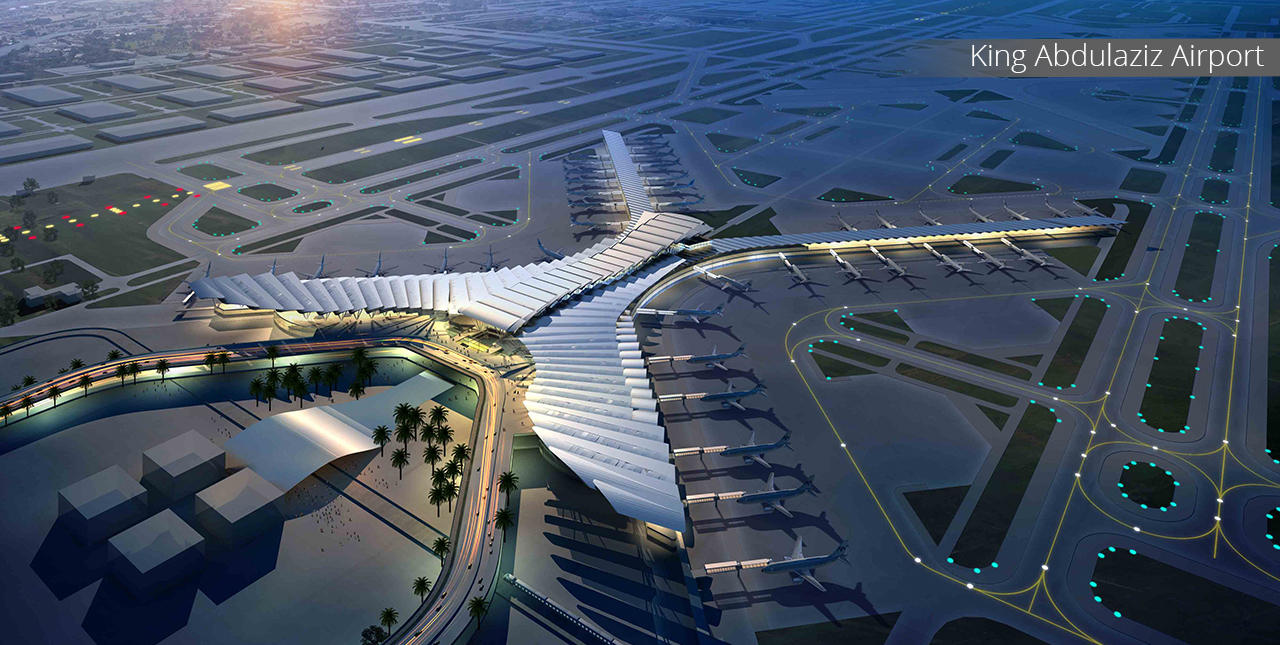

Surfaces with the highest light reflection

vega on Board (VLB) is a MC-PCB (Metal Core – Printed Circuit Board) material specially studied for high-power LEDs.

Compared with a silver-plated copper printed PCB, it offers numerous advantages in terms of performance and it increases the LED modules overall efficiency. Vega on Board (VLB) surfaces reflect light almost equally on all visible wavelengths, ensuring excellent color rendering. They are available in multiple thicknesses.

Alloy: 1090

Thickness: 0,75 mm - 1,00 mm

Width: max 1250 mm

Main advantages

High reflectivity

Energy efficiency

Lightness

High temperatures

Easy to shape

Need custom solutions?

Our experienced team is ready to offer you support tailored to your specific needs. Whether you are planning a new project or have questions about our solutions, don’t hesitate to contact us.